Heavy duty high head lined slurry pump

Materials:

High Chrome Alloy: high Chrome percentage’s available from 27-38% – Materials can be requested based on your working condition such as abrasiveness, impact, corrosiveness, PH levels, etc.

Material code reference:A05/A12/A33/A49/A61 and etc.

Description

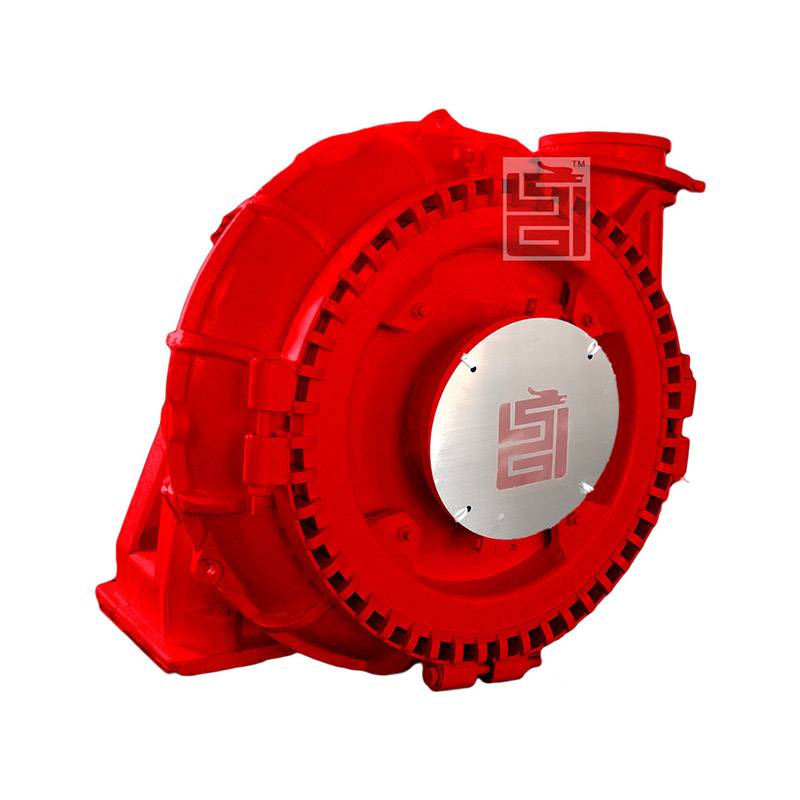

The Panlong H pump range is designed to produce high heads per stage at high pressures.Commonly used for long distance transport lines, the Panlong series H pump range can often satisfy application duties with a single pump where others require multiple pumps in series. As extensive exterior ribbing allows for higher heads to be reached with a single pump.

The high heads along with robuster wear parts makes these pumps some of the most rugged in the Panlong Slurry line. Bulked up wet end parts handle the toughest applications in the field.

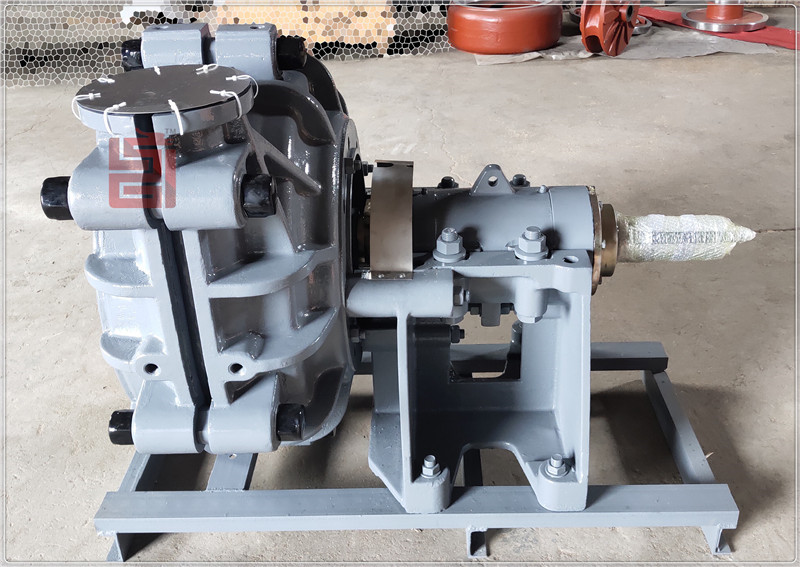

Each Panlong pump is carefully assembled and checked tolerance prior to hydraulic testing, allowing for immediate installation. Pumps can be fit up by customization to meet specific requirements from clients worldwide.

Conveying slurry is at the heart of a mine site, so we deeply know your pumping equipment is crucial to the task. Panlong pump could eliminate your existing pump vibrating, cavitating or leaking.

Key Feature:

1.Ductile iron ribs help casing to provide durability,strength and long service life

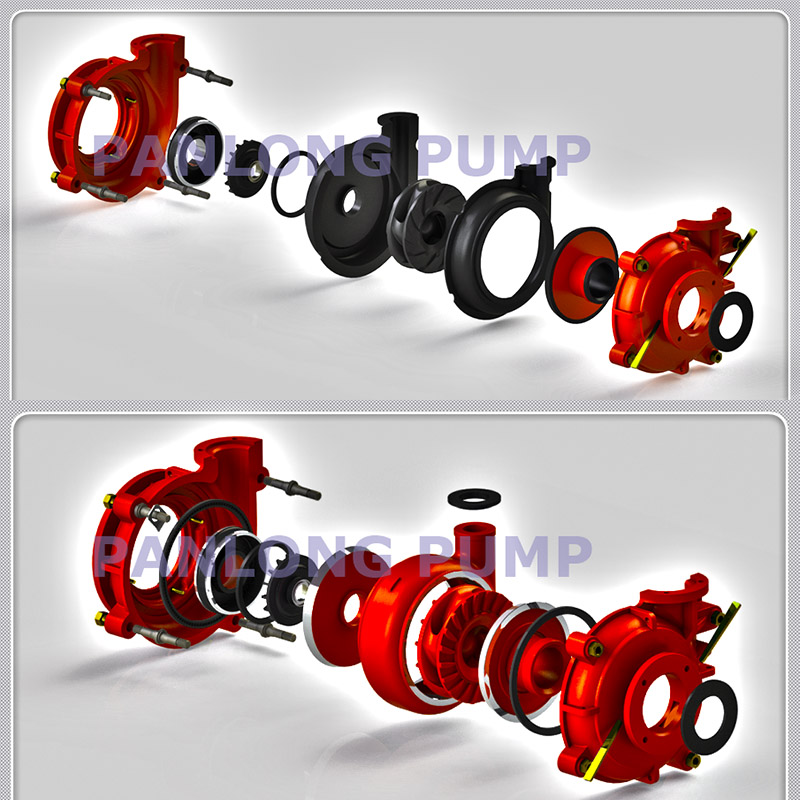

2.Large diameter, high efficiency impellers designed to achieve maximum wear life and low operating costs

3.Standard bearing cartridge (grease lubricated SKF bearings)extending shaft lifecycle and reducing unexpected shutdowns and maintenance costs.

4.Modular design inner liner(wet ends) is ALL metal fit-up .

5.Multiple options of sealing type adapted to particular liquids and applications (gland packing, mechanical seal, expeller shaft seal)